625-2RS Rubber-sealed Miniature Bearing 5×16×5mm

Get Latest Price| Payment Type: | T/T,L/C,Paypal |

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 100 Piece/Pieces |

| Transportation: | Ocean,Air,Express |

| Port: | Shanghai,Ningbo |

| Payment Type: | T/T,L/C,Paypal |

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 100 Piece/Pieces |

| Transportation: | Ocean,Air,Express |

| Port: | Shanghai,Ningbo |

Model No.: 625-2RS BEARING

Types Of: Ball

Structure: Deep Groove

Applicable Industry: Manufacturing Plant, Other

Number Of Columns: Single Row

Place Of Origin: China

| Selling Units | : | Piece/Pieces |

| Package Type | : | plastic tube +carton+pallet, as per customer's request |

| Picture Example | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

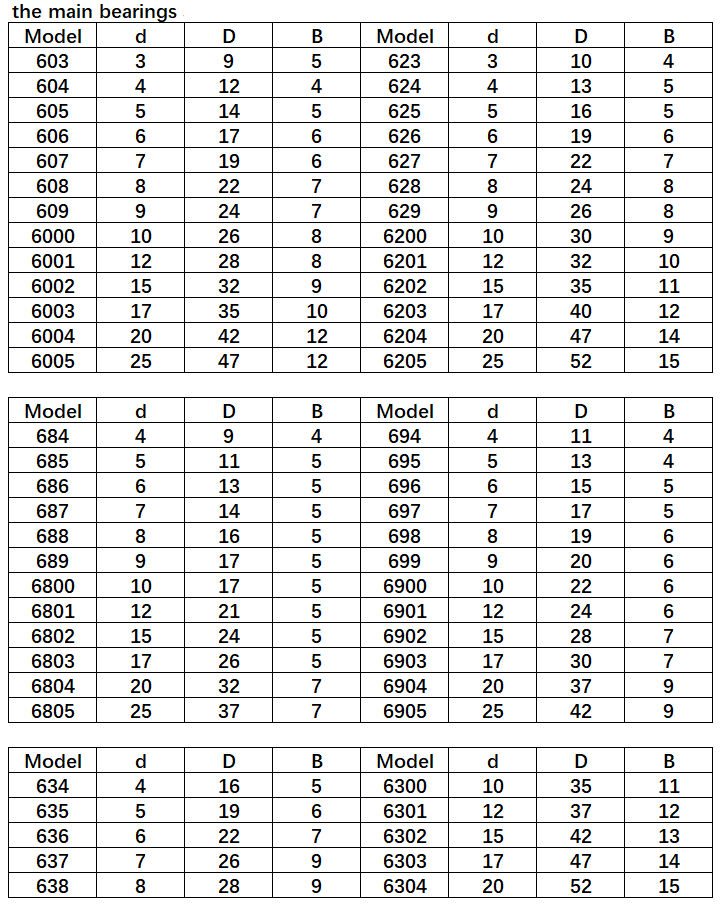

The 625-2RS Rubber-sealed Miniature Bearing 5×16×5mm is a high-performance miniature bearing specially designed for precision equipment. It adopts a double-sided NBR rubber seal (2RS) structure, providing IP54-level dust and water protection. It is particularly suitable for application scenarios with strict requirements for cleanliness and reliability, such as medical equipment, precision instruments, and small motors.

Stainless steel bearing: Benchmark for corrosion resistance performance

High-quality stainless steel materials such as AISI 440C, 304, and 316 are adopted. Through vacuum melting, precision forging, and special heat treatment processes, a martensitic or austenitic microstructure with high strength and hardness is formed. According to the ASTM B117 salt spray test, in the environment of 5% sodium chloride solution, there was no obvious corrosion phenomenon after continuous 48-1000 hours, and the surface hardness could reach HRC58-62. It is applicable to scenarios with extremely high requirements for corrosion resistance and cleanliness, such as food processing, medical devices, and Marine engineering, effectively avoiding equipment failures caused by corrosion and reducing maintenance costs.

Ball bearing: A classic of efficient transmission

Based on the point-contact rolling element design and combined with the high-precision ground inner and outer ring raceways, it achieves efficient transmission performance with low friction and high speed. Precision grade G10-G20 steel balls are adopted, with roundness error ≤0.5μm, surface roughness Ra≤0.08μm, and the friction coefficient during operation is as low as 0.005-0.01. After fatigue life testing (ISO 281 standard), the rated life (10 hours) can reach 8,000-30,000 hours. It is widely used in fields such as automated production lines, precision instruments, and power tools, providing stable and efficient power transmission for equipment.

Deep groove ball bearing: A model of load-bearing capacity and stability

By applying the symmetrical deep groove raceway structure design and combining with the optimized contact Angle parameters, it has excellent radial and axial load-bearing capacity. Verified by finite element analysis, it can withstand radial load coefficients (C) ranging from 2.8 to 50kN and axial load coefficients (Ca) ranging from 1.2 to 20kN, and is capable of simultaneously withstands bidirectional axial forces and relatively large radial forces. Under high-speed operation conditions (with a maximum speed of up to 25,000 r/min), through dynamic balance detection, the vibration value (Vrms) is ≤1.2mm/s and the noise level (dB) is ≤45. It is widely used in industrial equipment such as motors, pumps, and fans to ensure the stable operation of the equipment.

Non-standard bearing: Expert in customized drive solutions

Relying on a professional engineering R&D team and advanced CAD/CAM design system, we provide full-process customized services for special working conditions, non-standard dimensions, and customized performance requirements. From material selection (covering special alloy steel, ceramics, plastics, etc.), structural optimization (special sealing forms, asymmetric raceway designs, etc.) to tolerance grade customization (IT5-IT8 grades), all have been verified through ANSYS simulation analysis and bench tests. We have successfully delivered over 1,000 customized bearing solutions for fields such as aerospace, new energy equipment, and high-end machine tools, achieving a perfect match between products and equipment.

Small bearing: The core force of micro-precision transmission

Focusing on the research and development and manufacturing of micro bearings with a size range of Φ1mm to Φ20mm, we adopt micro-nano level processing technology, with dimensional accuracy controlled within IT5 to IT7 grades and roundness error ≤0.3μm. The internal structure is optimized to achieve a minimum friction torque of ≤0.05N · m. It is suitable for scenarios with extremely high requirements for spatial dimensions and operational accuracy, such as medical equipment (such as insulin pumps, endoscope drive systems), electronic and digital products (such as mobile phone cameras, drone gimbal), and precision instruments (such as atomic force microscopes), carrying precise operations with a tiny body.

Water pump bearing: The reliable guardian of the water pump system

For the working conditions of high humidity, strong vibration and alternating load in the operation of water pumps, special material formulas and structural designs are adopted. The bearing rings are carburized and quenched, with a surface hardness of HRC60-64 and good core toughness (impact absorption energy ≥35J). The sealing structure adopts a double-lip contact rubber seal and a labyrinth-type dust-proof design, with a waterproof rating of IP67, which can effectively resist the invasion of water vapor. Verified by the pump simulation test, the dynamic load coefficient (C) reaches 3.2-25kN. Under the working condition of continuous operation for 24 hours and vibration acceleration of 10m/s², the rated life (10 hours) exceeds 15,000 hours, providing stable and reliable support for water supply and drainage, agricultural irrigation, industrial circulating water systems, etc.

Relying on the collaborative advantages of our full range of bearing products and professional technical service capabilities, we continuously provide high-performance and highly reliable transmission solutions for the industrial sector, helping customers enhance equipment efficiency and promote technological upgrades in the industry.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.