689ZZ Micro Deep Groove Ball Bearing

Get Latest Price| Payment Type: | Paypal,L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 100 Piece/Pieces |

| Transportation: | Ocean,Air,Express |

| Port: | Shanghai,Ningbo |

| Payment Type: | Paypal,L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 100 Piece/Pieces |

| Transportation: | Ocean,Air,Express |

| Port: | Shanghai,Ningbo |

Model No.: 689ZZ bearing

Types Of: Ball

Structure: Deep Groove

Applicable Industry: Manufacturing Plant, Food &Amp; Beverage Factory, Other

Number Of Columns: Single Row

Place Of Origin: China

| Selling Units | : | Piece/Pieces |

| Package Type | : | plastic tube +carton+pallet, as per customer's request |

| Picture Example | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

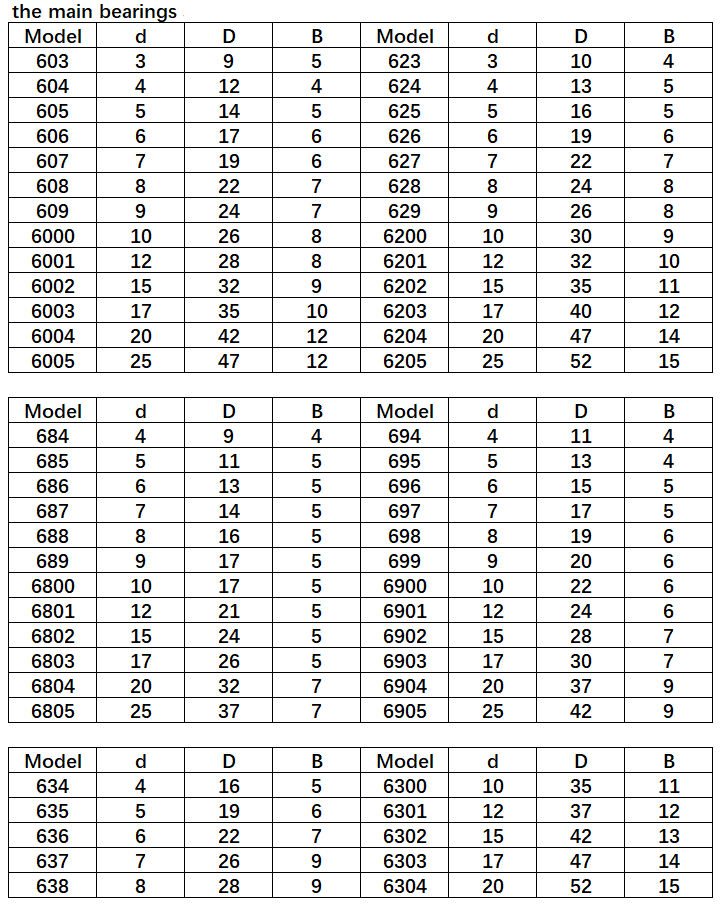

The 689ZZ Micro Deep groove ball bearing, with millimeter-level precision dimensions and outstanding craftsmanship, perfectly balances the load and rotational speed. It continuously outputs stable and reliable performance in tiny Spaces such as medical devices and intelligent equipment, and has become an indispensable "invisible gear" in modern precision industry. Just like our Stainless steel bearing, with a special alloy formula and vacuum heat treatment process, it can still maintain an extremely long service life of more than ten years in highly corrosive scenarios such as Marine engineering and chemical equipment. Ball bearing reduces the friction coefficient to the industry-leading level by optimizing the design of the ball curvature and contact Angle, endowing wind turbine main shafts and high-speed motors with strong and lasting kinetic energy.

The classic Deep groove ball bearing has undergone multiple generations of technological iterations. It not only continues to shine in traditional fields such as automotive chassis and textile machinery, but also achieves performance breakthroughs in the new energy track, contributing to the improvement of industry efficiency. Our Non-standard bearing customization service, relying on 3D modeling and finite element analysis technology, can deliver from drawings to finished products within the fastest 72 hours and has successfully solved thousands of special working condition problems. Small bearing integrates the nanoscale polishing process into the production process, with an accuracy of up to P4 grade, providing core support for aerospace precision components. The Water pump bearing innovatively adopts a double labyrinth sealing structure, which can ensure trouble-free operation for ten thousand hours even in extreme water environments with excessive sediment content.

Each bearing is a challenge to the limit, from micro precision to macro heavy load. With our full range of bearing matrix, we continuously inject innovative impetus into global industrial transmission systems.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.