698-2RS Deep Groove Ball Bearing

Get Latest Price| Payment Type: | Paypal,T/T,L/C |

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 100 Piece/Pieces |

| Transportation: | Express,Air,Ocean |

| Port: | Shanghai,Ningbo |

| Payment Type: | Paypal,T/T,L/C |

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 100 Piece/Pieces |

| Transportation: | Express,Air,Ocean |

| Port: | Shanghai,Ningbo |

Model No.: 698-2RS bearing

Types Of: Ball

Structure: Deep Groove

Applicable Industry: Other, Manufacturing Plant

Number Of Columns: Single Row

Place Of Origin: China

| Selling Units | : | Piece/Pieces |

| Package Type | : | plastic tube +carton+pallet, as per customer's request |

| Picture Example | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

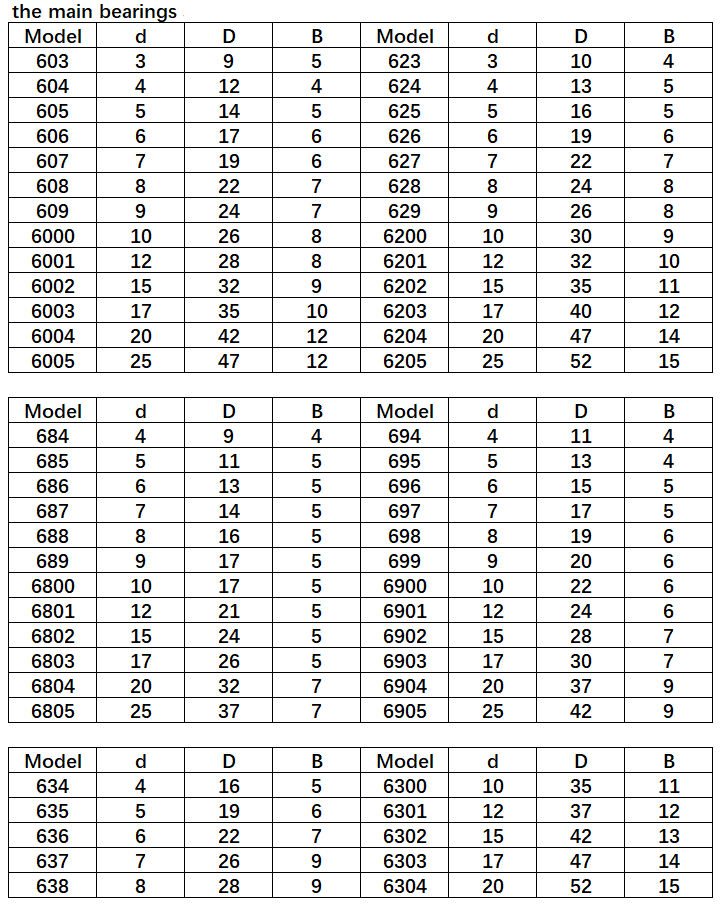

The 698-2RS Deep groove ball bearing achieves outstanding performance with exquisite craftsmanship. The double-sided seal (2RS) design effectively blocks the intrusion of impurities. The deep groove ball structure endows it with excellent radial and axial load-bearing capabilities. It can operate stably whether in high-speed operation or complex load conditions. Provide reliable power support for automated production lines, precision instruments and other equipment.

This echoes the technical strength of our multi-component bearing matrix. Stainless steel bearing, with its special metallurgical formula and surface treatment technology, can maintain stable operation continuously in highly corrosive environments such as chemical engineering and Marine engineering, and increase the corrosion resistance life by more than 50%. Ball bearing reduces the friction coefficient to the industry-leading level by optimizing the roundness of the balls and the arc of the raceways, injecting efficient kinetic energy into wind power and machine tool equipment. Classic Deep groove ball bearings such as 698-2RS, after multiple rounds of structural strengthening and material upgrading, are widely applicable to fields such as automobiles and electrical motors.

Our Non-standard bearing customization service, relying on 3D modeling and simulation analysis technology, has achieved full-process control from demand diagnosis to finished product delivery, and has successfully solved special working condition problems in fields such as ships and military industry. Small bearing focuses on micro-precision manufacturing, with micron-level processing accuracy meeting the strict standards of aerospace and medical equipment. In view of the high-frequency vibration and medium erosion characteristics of fluid machinery, the Water pump bearing adopts a composite sealing and wear-resistant coating process to ensure long-term operation in complex water environments such as sewage and seawater. All types of bearings work in concert to drive every precise turn in the industrial field with ultimate quality.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.