In the intricate realm of precision transmission, the performance of every bearing serves as a linchpin for the accuracy and efficiency of equipment operation. Drawing upon our profound technological expertise and stringent quality control protocols, we have established a comprehensive product matrix encompassing Stainless steel bearing,

Ball bearing,

Deep groove ball bearing, Non-standard bearing,

Small bearing, and

Water pump bearing. This portfolio is designed to deliver professional and reliable transmission solutions to industries worldwide.

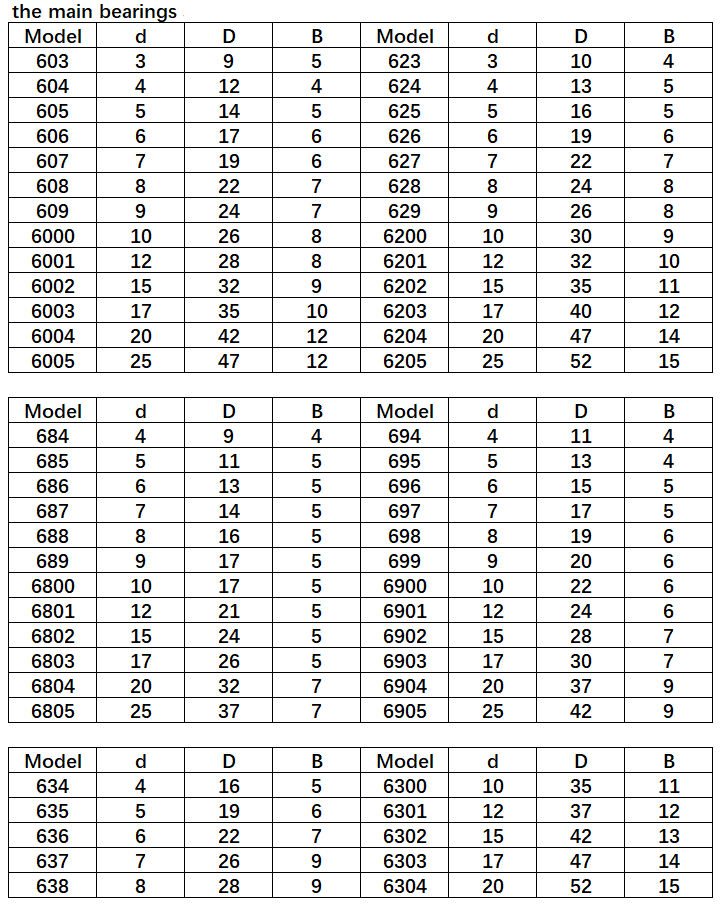

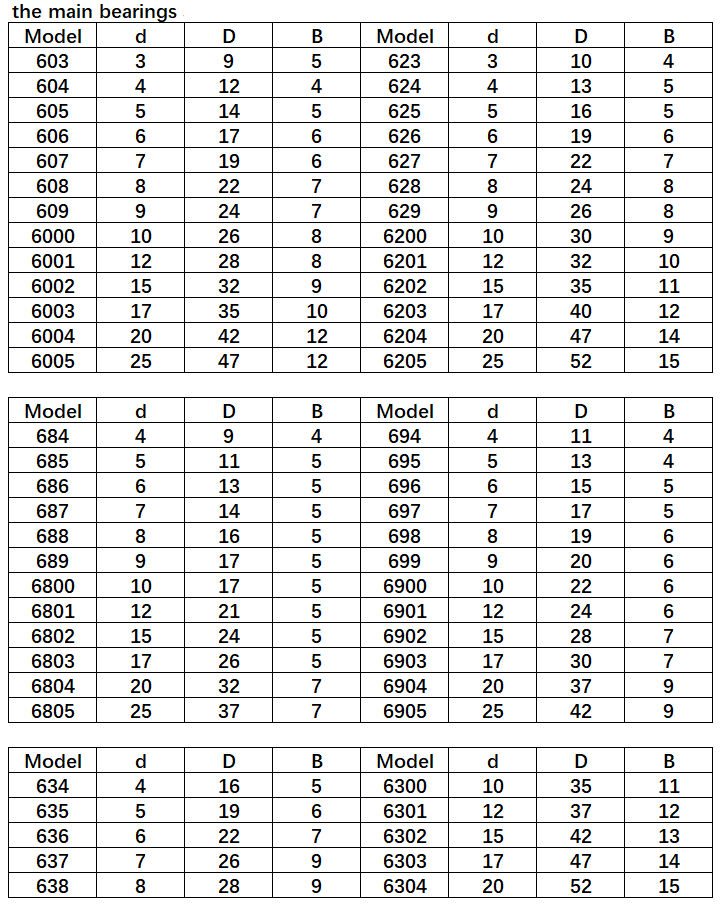

The 634ZZ ultra-thin bearing, measuring 4mm×16mm×5mm, stands as a paragon of thin - profile engineering within the Small bearing category. Its ultra - slim dimensions are a testament to meticulous design, enabling seamless integration into precision equipment with exacting space constraints. Whether it is the zoom mechanism of miniature cameras or the intricate transmission systems of smartwatches, this bearing excels in optimizing space utilization. The double dust cover (ZZ) structure, crafted from high - strength stamped steel, is meticulously joined to the bearing's inner and outer rings via precision laser welding. With an IP54 protection rating, it forms an impenetrable shield against dust, debris, and other contaminants. In dusty industrial workshops or within the enclosed spaces of electronic devices, it safeguards the integrity of internal precision components, effectively minimizing maintenance costs and downtime risks associated with equipment wear.

In terms of material science and manufacturing processes, the 634ZZ bearing is fabricated from high - carbon chromium bearing steel of equivalent quality to Stainless steel bearings. Through a series of meticulous treatments including vacuum quenching, tempering, and deep cryogenic processing, its surface hardness reaches HRC60 - 62, resulting in a dense wear - resistant layer that offers exceptional resistance to abrasion and corrosion. As a distinguished member of the Ball bearing family, it is equipped with precision - grade G10 steel balls and features the classic symmetrical Deep groove raceway design characteristic of Deep groove ball bearings. Rigorous testing in professional mechanical laboratories, combined with advanced computer simulations, has verified its ability to withstand a radial load of 0.7kN and an axial load of 0.25kN. With a friction coefficient as low as 0.005, the bearing operates with remarkable efficiency. Even at high rotational speeds of 12,000 r/min, it maintains a vibration value ≤6.5m/s² and a noise level ≤41dB, ensuring stable and efficient power transmission for high - precision, high - speed micro - transmission systems. This makes it an ideal choice for applications where the operational accuracy and stability of precision optical instruments and micro - automation equipment are of paramount importance.

For projects with unique specification requirements, our Non - standard bearing customization service offers tailored solutions. Staffed by a team of experienced professional engineers and leveraging state - of - the - art CAD/CAM design systems, we provide comprehensive customization options. From optimizing material properties and innovating sealing structures to precisely controlling tolerance grades, our approach is highly personalized. In micro water pump applications, the 634ZZ ultra - thin bearing has demonstrated outstanding performance. Subjected to rigorous tests simulating high - frequency start - stop cycles and continuous vibration, it achieves a dynamic load coefficient (C) of 0.85kN. After 1200 hours of continuous operation, the change in bearing clearance remains ≤0.006mm, showcasing stability on par with Water pump bearings. This ensures the long - term, stable, and efficient operation of micro water pump systems.

From the precise operations of microscopic instruments to the core transmissions of industrial automation equipment, the 634ZZ ultra - thin bearing, with its exceptional performance, collaborates seamlessly with our full range of core products. Together, they provide a robust foundation for mechanical operations, propelling industries towards new frontiers of efficiency and stability.