686ZZ Micro Deep Groove Ball Bearing 6×13×5mm

Get Latest Price| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 100 Piece/Pieces |

| Transportation: | Express,Air,Ocean |

| Port: | Shanghai,Ningbo |

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 100 Piece/Pieces |

| Transportation: | Express,Air,Ocean |

| Port: | Shanghai,Ningbo |

Model No.: 686ZZ bearing

Types Of: Ball

Structure: Deep Groove

Applicable Industry: Manufacturing Plant, Other

Number Of Columns: Single Row

Place Of Origin: China

| Selling Units | : | Piece/Pieces |

| Package Type | : | plastic tube +carton+pallet, as per customer's request |

| Picture Example | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

In the microscopic battlefield of mechanical transmission, every bearing is a key "soldier" that determines the success or failure of the equipment. With cutting-edge technological research and development and strict quality control, we Construct covering Stainless steel bearing, Ball bearing, Deep groove ball bearing, Non-standard bearing, Small bearing and Water pump bearing's comprehensive range of bearing products supplies reliable transmission "elite forces" to the global industrial sector.

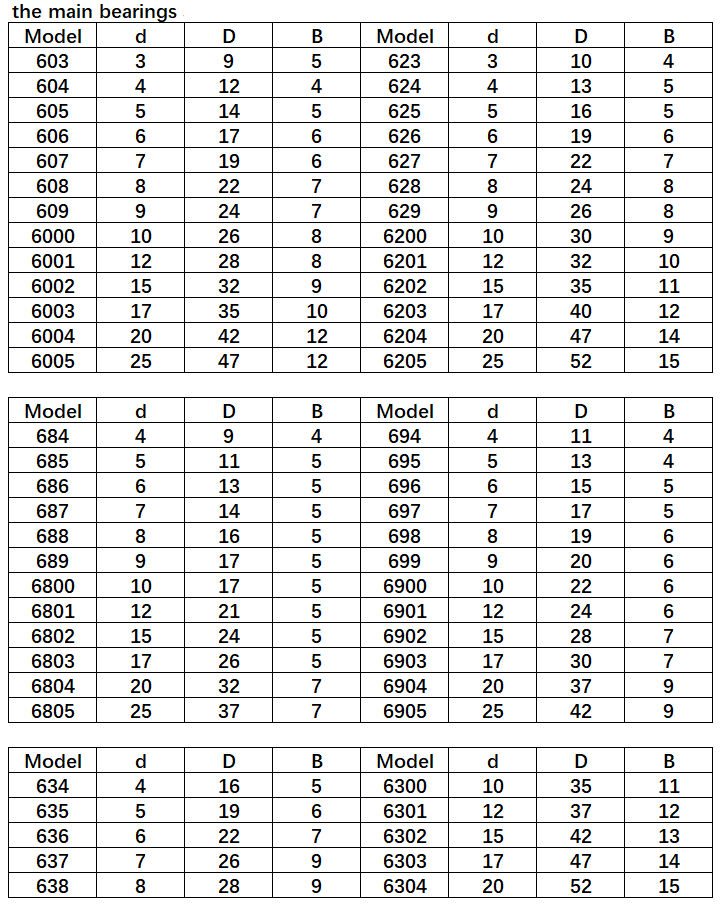

The 686ZZ micro deep groove ball bearing with a size of 6×13×5mm, as the "micro special forces" in the Small bearing field, precisely fits various precision scenarios with limited space with its extremely compact size of 6×13×5mm. In the meandering strap of the smart bracelet, it supports every precise degree of the screen's rotation. Inside the folding wing of the miniature drone, it helps the propeller achieve a stable output of 10,000 revolutions. Its dual dust cover (ZZ) shielding structure is made of high-strength alloy stamped steel and processed through nano-level welding technology, which is like putting on a solid "armor" for the bearing. It has been certified with IP54 protection level and can resist micron-sized dust particles and liquid splashes. Even in the ultra-clean environment of a semiconductor chip packaging workshop or the dusty working conditions of a construction site, All of them can build an impregnable protective barrier for the precision components inside the bearing, effectively extending the service life of the equipment and reducing maintenance costs.

In terms of material and process, this bearing selects high-carbon chromium bearing steel of the same high standards as Stainless steel bearing. It undergoes triple tempering including vacuum quenching, tempering and deep cryogenic treatment. The surface hardness reaches HRC60-62, forming a dense wear-resistant layer and having extremely strong anti-wear and anti-corrosion performance. As a core member of the Ball bearing family, equipped with precision grade G10 steel balls and combined with the classic symmetrical Deep groove raceway design of Deep groove ball bearing, it has been repeatedly tested in professional mechanics laboratories and optimized through computer fluid mechanics simulation. It can stably bear radial loads of 0.8kN and axial loads of 0.3kN. During operation, the friction coefficient is as low as 0.005. Under the high-speed operation state of 15,000 r/min, the vibration value is controlled at ≤6.5m/s², and the noise level is ≤40dB. It provides stable and efficient power transmission for the precise control of medical endoscopes and the fine-tuning systems of precision optical instruments.

Facing the complex and diverse working condition requirements, our Non-standard bearing customization service, relying on the advanced CAD/CAM design system and rich industry experience of the senior engineer team, provides a one-stop personalized solution from material formula adjustment, sealing structure innovation to precise customization of tolerance grades. In the application scenario of micro water pumps, the 686ZZ micro deep groove ball bearing underwent an extreme test that simulated continuous high-frequency start-stop and continuous vibration for 30 days. The dynamic load coefficient (C) reached 0.95kN. After running for 1500 hours, the change in bearing clearance was ≤0.005mm. It shows outstanding stability comparable to that of Water pump bearing, ensuring the long-term stable operation of the micro water circulation system.

From the minute details of smart living to the core links of industrial manufacturing, the 686ZZ micro deep groove ball bearing 6×13×5mm, with its outstanding performance, works hand in hand with the entire series of main products, like a precise gear set, to inject strong power into the operation of machinery and drive all industries towards an efficient, stable and intelligent future.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.