In the microscopicof industrial transmission, each bearing type plays a pivotal role in ensuring the stable operation of equipment. Drawing on our extensive technological expertise and stringent quality control mechanisms, we have established a comprehensive product matrix encompassing Stainless steel bearing,

Ball bearing,

Deep groove ball bearing, Non-standard bearing,

Small bearing, and

Water pump bearing. This portfolio is designed to deliver professional and reliable transmission solutions across diverse industries worldwide.

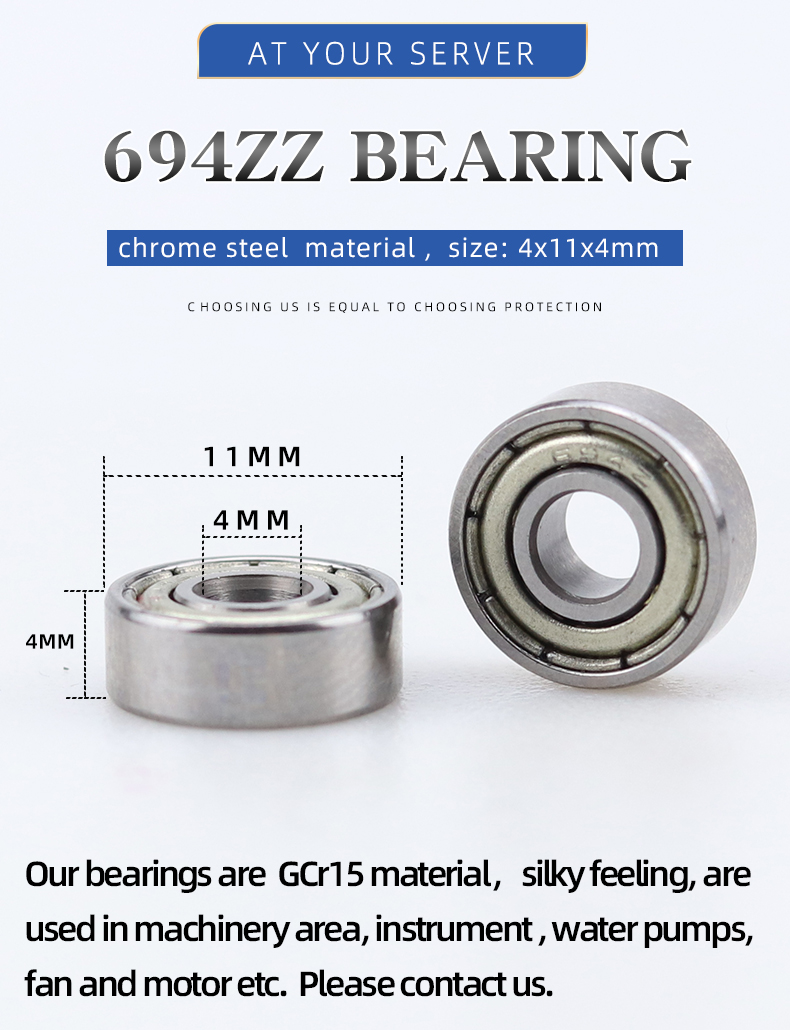

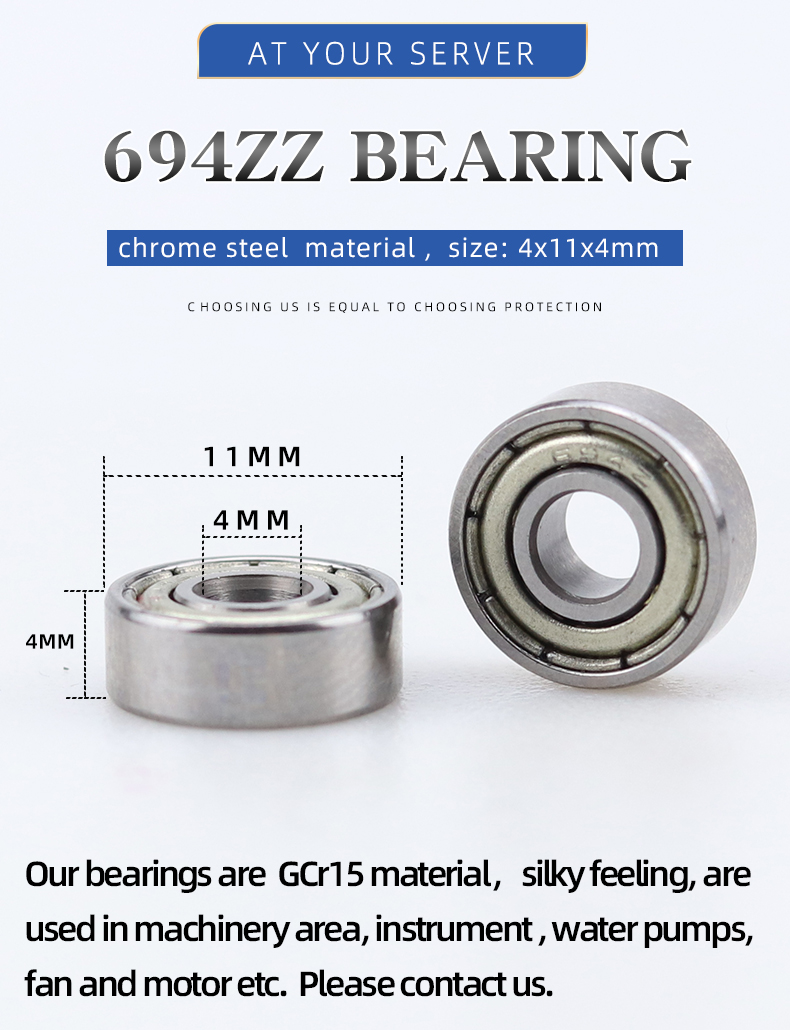

The 694ZZ ultra-miniature shielded bearing, measuring 4×11×4mm, stands as an exemplary model in the realm of Small bearings, thanks to its incredibly compact dimensions. Its double dust cover (ZZ) shielding structure, fabricated from high-strength ultra-thin stamped steel, is seamlessly integrated with the bearing's inner and outer rings through nano-level welding technology. Certified with an IP54 protection rating, it acts as an impregnable fortress, effectively repelling micron-sized dust particles and fine debris. Whether deployed in semiconductor chip manufacturing workshops with stringent cleanliness requirements or within the dusty confines of microelectronic devices, it safeguards the integrity of the bearing's internal precision components, significantly reducing equipment maintenance costs and minimizing downtime risks caused by impurity-induced wear.

In terms of materials and manufacturing processes, this bearing utilizes high-carbon chromium bearing steel of the same premium quality as Stainless steel bearings. Through a series of meticulous procedures, including vacuum quenching, tempering, and deep cryogenic treatment, its surface hardness reaches HRC60 - 62, forming a dense wear-resistant layer that confers excellent abrasion and corrosion resistance. As a distinguished member of the Ball bearing family, it is equipped with precision-grade G10 steel balls and features the classic symmetrical Deep groove raceway design characteristic of Deep groove ball bearings. Rigorous testing in professional mechanical laboratories, coupled with advanced computer simulations, has verified its ability to stably support a radial load of 0.55kN and an axial load of 0.2kN. During operation, its friction coefficient drops as low as 0.005. Even at a high rotational speed of 15,000 r/min, the vibration value remains ≤6m/s² and the noise level is ≤40dB, ensuring stable and efficient power transmission for high-precision, high-speed micro-transmission systems. This makes it an ideal choice for meeting the exacting requirements for operational accuracy and stability in precision optical instruments, micro-automation equipment, and other applications.

For projects with unique specification requirements, our Non-standard bearing customization service offers tailored solutions. Our team of professional engineers, leveraging advanced CAD/CAM design systems and rich industry experience, provides comprehensive personalized services. From optimizing material properties and innovating sealing structures to precisely customizing tolerance grades, we ensure that every aspect aligns with your specific needs. In the context of micro water pump applications, the 694ZZ ultra-miniature shielded bearing has undergone rigorous tests simulating high-frequency start-stop cycles and continuous vibration. Its dynamic load coefficient (C) reaches 0.7kN, and after 1200 hours of continuous operation, the change in bearing clearance is ≤0.005mm. This performance demonstrates outstanding stability comparable to that of Water pump bearings, guaranteeing the long-term stable and efficient operation of micro water pump systems.

From the precise operations of microscopic precision instruments to the core transmissions of industrial automation equipment, the 694ZZ ultra-miniature shielded bearing, with its exceptional performance, collaborates seamlessly with our full range of core products. Together, they form a robust foundation for mechanical operations, propelling various industries towards new heights of efficiency and stability.