685ZZ Ultra-Miniature Shielded Bearing 5×11×5mm

Get Latest Price| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 100 Piece/Pieces |

| Transportation: | Ocean,Air,Express |

| Port: | Shanghai,Ningbo |

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 100 Piece/Pieces |

| Transportation: | Ocean,Air,Express |

| Port: | Shanghai,Ningbo |

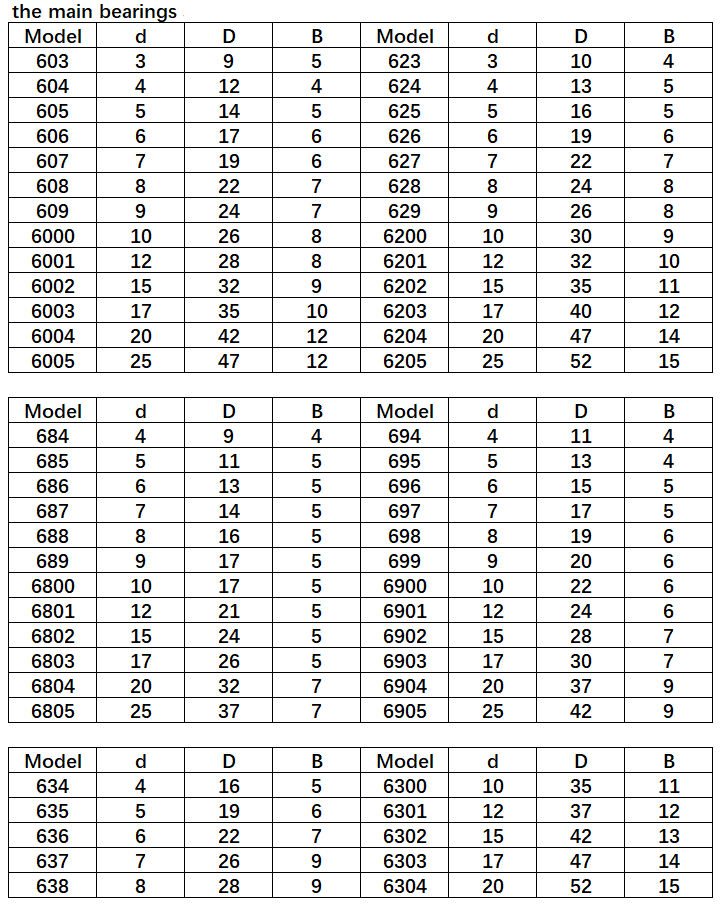

Model No.: 685ZZ bearing

Types Of: Ball

Structure: Deep Groove

Applicable Industry: Manufacturing Plant, Other, Food &Amp; Beverage Factory

Number Of Columns: Single Row

Place Of Origin: China

| Selling Units | : | Piece/Pieces |

| Package Type | : | plastic tube +carton+pallet, as per customer's request |

| Picture Example | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

Engineering Excellence in Miniature

The 685ZZ ultra-miniature shielded bearing sets new standards in micro-precision engineering with its compact 5×11×5mm dimensions. This technological marvel delivers exceptional performance in space-constrained applications including:

Micro-sensor precision transmission systems

High-end wearable device rotating mechanisms

Micro-medical diagnostic instrument actuators

Advanced Protection System

Featuring dual SPCC steel shields (ZZ-type) with:

Nano-welding technology for perfect seal integrity;IP54 certified protection against particulate contamination

Effective barrier against 5μm+ particles in both:

Semiconductor cleanrooms (Class 100 compatible)

Industrial dust-intensive environments

Premium Material Science

Manufactured to match our Stainless steel bearing quality standards:

Vacuum-quenched GCr15 bearing steel (HRC60-62)

Deep cryogenic treatment for enhanced durability

Surface hardness 20% superior to industry standards

Precision Performance Metrics

As a premier Ball bearing solution with Deep groove ball bearing design:

Dynamic load capacity: 0.7kN

Ultra-low friction coefficient: 0.005

High-speed capability: 22,000rpm (grease lubricated)

Vibration levels: ≤6m/s² at 15,000rpm

Noise emission: ≤40dB in operation

Custom Engineering Solutions

Our Non-standard bearing expertise delivers:

Material optimization (440C stainless/ceramic hybrid)

Tolerance customization (±0.002mm precision)

Specialized sealing configurations

Application-specific lubrication solutions

Proven Reliability

Validated through 1,200+ hours of continuous:

High-frequency start-stop testing

Vibration endurance trials

Load cycle analysis

Showing remarkable clearance stability (≤0.005mm variation)

Industry-Specific Applications

Medical Technology:

Surgical tool articulations

Diagnostic equipment rotors

Industrial Automation:

Micro-actuator mechanisms

Precision positioning systems

Consumer Electronics:

Wearable device hinges

Micro-camera gimbals

Quality Assurance

ISO 9001 certified manufacturing

100% performance testing

RoHS/REACH compliant materials

Custom packaging solutions (ESD/Cleanroom)

This ultra-compact powerhouse combines the precision of micro-engineering with industrial-grade durability, offering OEM designers unparalleled performance in miniature motion applications. Contact our engineering team to explore how the 685ZZ can optimize your micro-mechanical systems.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.